iPhone Aftermarket Glass Lens Factory Tour in China

Front Glass Lens on iPhone is an indispensable part as users get access to their phones. And it can also affect user experience with intuitive feeling. Widely applied as they are, have you got any idea where they came from? Let’s take a closer look at the production process of glass lens in the factory!

Glass Lens Factory Production Process

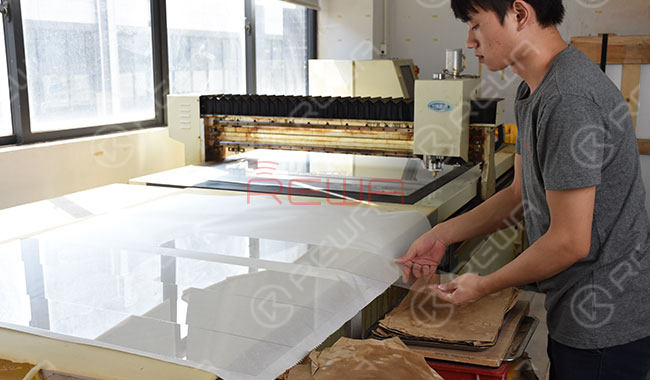

Glass Cutting

Cut glass pieces into 4.7 inches, 5.5 inches and so on with CNC Cutting Machine.

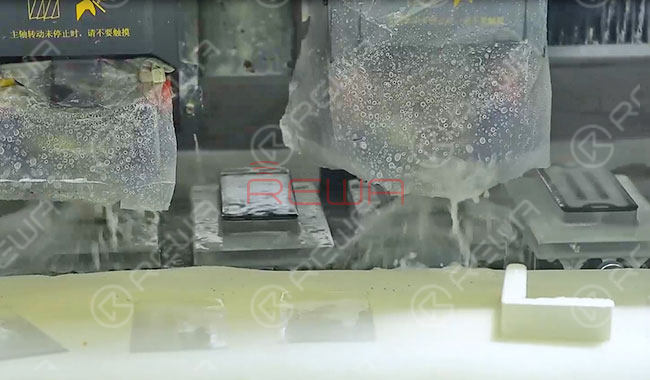

Glass Grinding

Make holes, rounded edges and 2.5D edges on glass pieces with CNC Grinding Machine.

Glass Polishing

Finish detailed polishing with glass polishing powder and polishing blanket.

Ultrasonic Cleaning

Clean semi-finished glass lens multiple times with Ultrasonic Cleaning Machine and special cleaning agents. Once finished, evaluate cleaning effect.

Tempering

Place semi-finished glass lens into the High-Temperature Tempering Furnace for 4 hours at 400℃. Once finished, take out the glass lens with bridge crane. Cooldown till room temperature after tempering process, then soak all glass lens into the water and run cosmetic inspection.

Silk Screen Making

Make the Silk Screen for printing and then transfer all glass lens to the special-designed printing tray.

Silk Screen Printing

The dust-free printing workshop comes with Automatic Screen Printing Machine and glass lens materials, two-rounds of silk screen printing and High-precision Optical Measurement System. All glass lens materials are sent into Automatic Screen Printing Machine for printing.

Mount the silk screen to the printing machine. Finish the first round of printing with Automatic Screen Printing Machine.

Baking

Send all products to the paint baking room for paint baking.

Once finished, run the second round of printing with Automatic Screen Printing Machine. Then send all products into the paint baking room for paint baking.

Detect the screen printing effect of glass lens with High-precision Optical Measurement System.

Ultrasonic Cleaning

Transfer all glass lens to the special-designed cleaning tray. Clean glass lens with Ultrasonic Cleaning Machine and special cleaning agents. Each piece of glass lens should go through 11 rounds of professional cleaning.

All glass lens are then sent to the Glass Lens with Bezel workshop after package.

Cosmetic Inspection

Run cosmetic inspection of glass lens - ensure good appearance and good surface effect.

Run cosmetic inspection of bezels - ensure there is no damage to bezels.

Plasma Treatment

Start scaffold surface treatment with Plasma Surface Treatment System so as to provide good conditions for adhesive attachment.

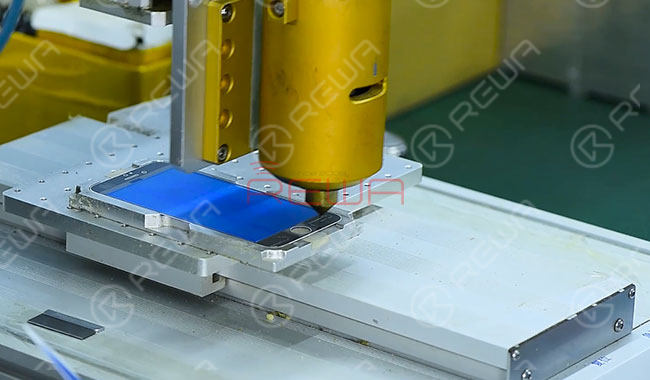

Fluid Dispensing

Program the Fluid Dispensing Machine and complete fluid dispensing process with specified Fluid (Cold Glue).

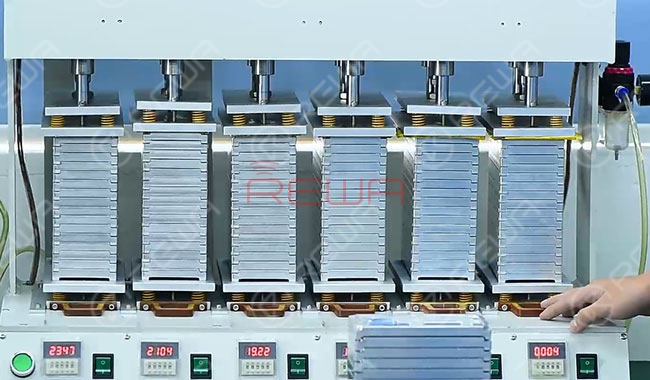

Bezel Assembling

Complete the alignment of glass lens and bezels in the special mold.

Place all products into the Bezel Assembling Machine for 40 minutes.

Once finished, run inspection of finished products.

Package all Qualified Glass Lens with Bezel.

You can also read our iPhone X OLED Screen Total Teardown Analysis.

No Comments

0

0

Share

Apr 23, 2021

ABOUT REWA

REWA is a world leading electronics repair business solutions provider who was founded in 2008 in HongKong. We are committed to delivering one-stop services covering Sourcing Solution, Technical Support Solution as well as Recycle & Resell Solution.

Sign In

Sign In

Shop

Shop

Academy

Academy